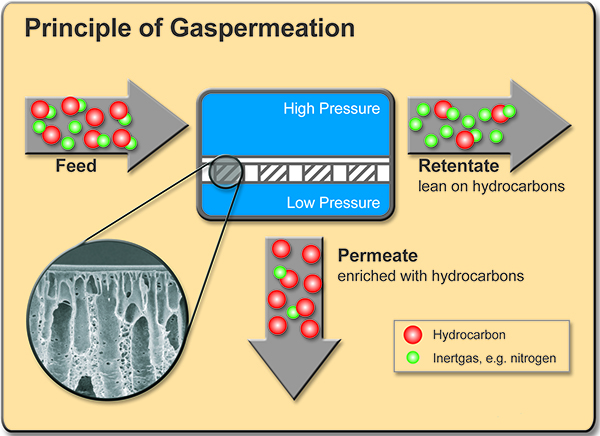

Today membrane-based separation processes are state-of-the-art, and in some areas this technology has become the leading process solution. This has been made possible by the development and continuous improvement of efficient and selective polymer membranes that provide the thermal, chemical and mechanical stability necessary for industrial use. Integrating the membranes into suitable module designs ensure reliable and safe operation.

Membranes are used in many applications in the chemical, petrochemical and oil/gas industries where liquid or gaseous mixtures containing hydrocarbons need to be treated. This can serve recycling, emission protection or other operational requirements.

One milestone in this development was the successful implementation of the gas permeation process for selectively separating organic vapours from exhaust air, and especially the treatment of vapours released during the distribution and storage of highly volatile hydrocarbons. Accompanied by related environmental protection legislation in many countries, a large number of membrane systems has been installed and successfully operated since 1988. This now makes membrane technology a leading technology in the field of industrial gasoline vapour recovery.

Based on this experience, further gas permeation applications have been successfully implemented, for example, in the olefin industry. Today hundreds of industry-scale plants are successfully in operation using HYTEC technology.

Based on this experience, further gas permeation applications have been successfully implemented, for example, in the olefin industry. Today hundreds of industry-scale plants are successfully in operation using HYTEC technology.