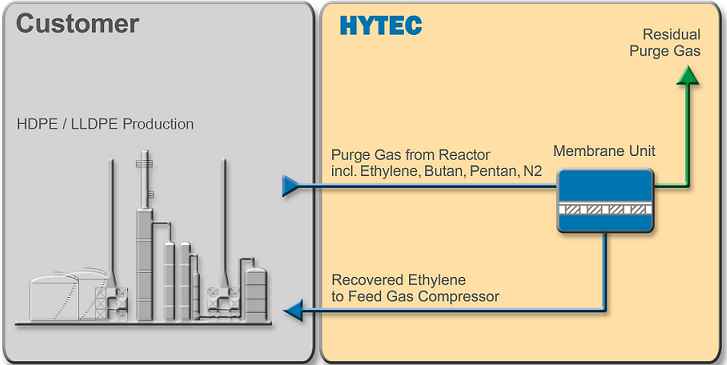

The HYTEC Ethylene Recovery Unit is an easy

add-on system and can be considered for new and existing process installations.

The purge gas stream containing the ethylene monomer

and inert gas, is

typically pressurised and fed into the membrane system, while the permeate side

of the membrane separation stage is fed back into the existing process gas

compressor’s

suction side. By means of the resulting pressure difference and

the hydrocarbon selective membrane material, the purge gas stream is separated

into off-gas, enriched with inert gas, and

the recycled ethylene-rich permeate

stream. No other equipment or machinery is usually required making this a very

simple and reliable process solution.

The benefits

• Easy installation in new plants and easy retrofit of existing systems

• Easiest solution in comparison to other technologies – only a membrane separator is required

• Very short return on investment

• Low maintenanceThe benefits• Safe and reliable operation• Tailor-made design to meet customer’s codes and specifications