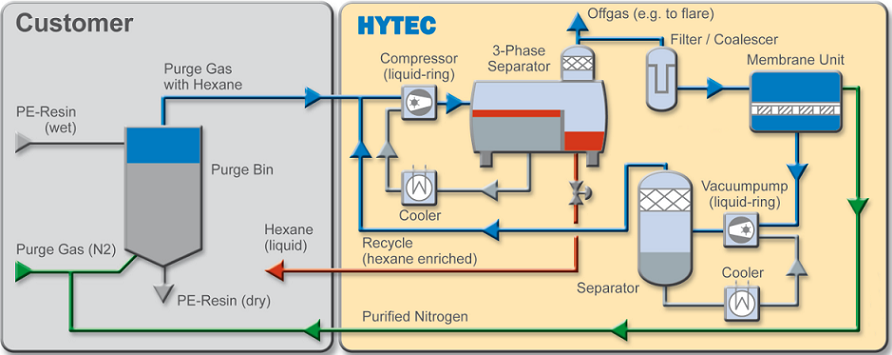

The HYTEC Hydrocarbon Recovery Unit is a portfolio of specially developed and customised process solutions to meet emissions legislation and minimise the loss of product

and profit by the recovery of valuable hydrocarbon.

The membrane separation is combined with other unit operations such as absorption, condensation, extraction etc. These hybrid processes are very efficient and enable the

customer to operate at the highest economic and ecological efficiency.

A typical application is powder degassing in slurry-type PE plants. Polymer is flashed and stripped with hot nitrogen and the released purge gas consisting of nitrogen and solvents

like butane, pentane and hexane can be processed using a sophisticated HYTEC hydrocarbon recovery technology. The liquefied solvent and the purified nitrogen can be re-used.

Another typical application is the vent gas from PE plants. The vent gas coming from the overhead of the upstream separator still contains a high amount of butane and pentane.

The HYTEC Hydrocarbon Recovery Unit separates the butane and pentane from the nitrogen before it is fed back to the suction side of the vent recovery compressor.